REMOVAL FROM SERVICE

A BINDER SHALL BE REMOVED FROM SERVICE IF ANY OF THE FOLLOWING CONDITIONS EXIST:

- > Hooks are worn, bent, distorted, twisted, stretched or cracked

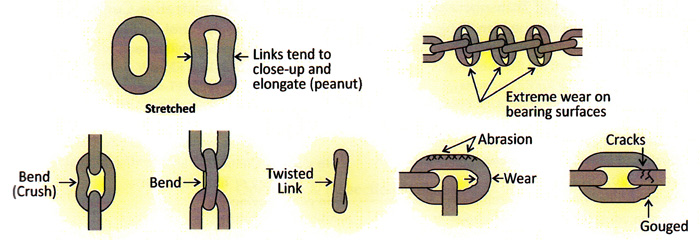

- > Links are bent, gouged, distorted, stretched, cracked or worn

- > No welding on any component is allowed with the exception of the initial factory production welds on the components during assembly

- > Clevis on pivot is worn, bent, distorted, or cracked

- > Pawl does not engage

- > Gear is worn, chipped, or cracked.

- > Markings are missing, incomplete, illegible, or incorrect

- > Excessive rust

- > End fitting threads are worn, bent, distorted or will not turn

- > Bent or deformed handle

- > Swivel sockets and or ball worn or deformed

OUT-OF SERVICE CRITERIA FOR CHAIN LINKS AND LOAD BINDERS

OBVIOUSLY DISTORTED OR STRETCHED LOAD BINDERS AND FITTINGS

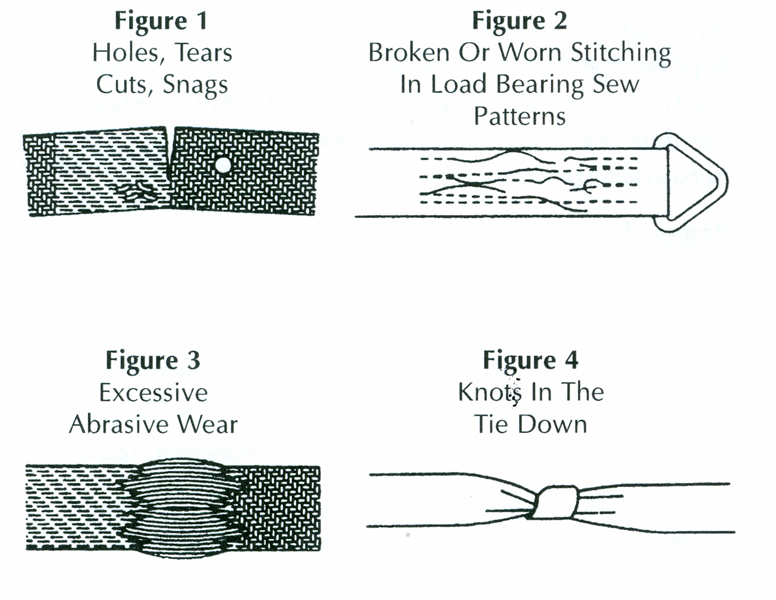

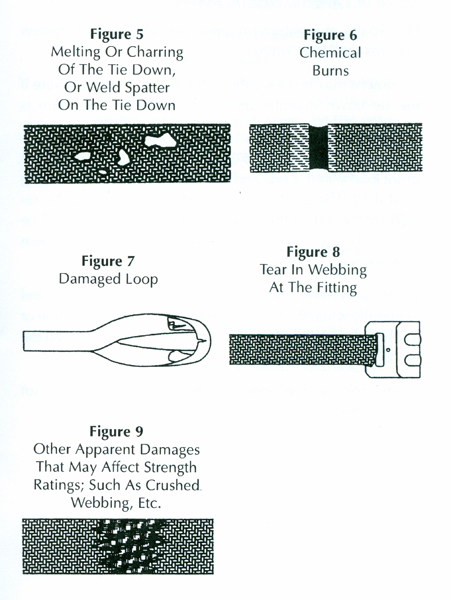

Inspection, Care & Use of Synthetic Web Tie Downs A tie down shall be removed from service if any of the following are visible:

- > Holes, tears, cuts, snags or embedded particles which cause doubt as to the strength of the tie down.

- > Broken or worn stitching in load-bearing stitch patterns.

- > Excessive Abrasion Wear.

- > Knots in any part of the webbing.

- > Melting, charring or weld spatter on any part of the webbing.

- > Acid or alkali burns

- > Signs of ultra-violet light degradation.

- > Pitting, corrosion, cracked, distorted or broken buckles or end fittings.

- > The working load limit assigned by the tie down manufacturer is no longer visible.

Inspection, Care & Use of Synthetic Web Slings

INSPECTION

A web sling shall be REMOVED FROM SERVICE if any of the identification items are missing or any of the following are visible.

IDENTIFICATION

Synthetic fiber web slings must be permanently identified with the a. Manufacturer’s name or mark, b. Manufacturer’s code or stock number, c. Working load limits for the types of hitches permitted, and d. Type of synthetic web material.

REMOVED FROM SERVICE

- > If sling rated capacity or sling material identification is missing or not readable.

- > Acid or alkalis burns

- > Melting, charring or weld spatters on any part of the web sling.

- > Holes, tears, cuts, snags or embedded particles.

- > Broken or worn stitching in load bearing splices.

- > Excessive abrasive wear.

- > Knots in any part of the web sling.

- > Excessive pitting, or corrosion, or cracked, or distorted, or broken fittings.

- > Any other visible damage that causes doubt as to the strength of the sling.